Pressure Instrumentation

- Products

- Pressure Instrumentation

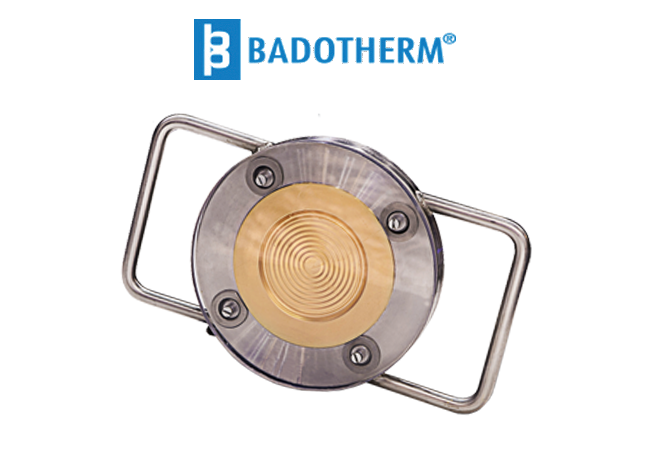

Gold-Coated Seals:

Gold-Coated Seals are used for protection against Hydrogen Permeation. Though hydrogen is not normally considered corrosive, there are specific circumstances under which it can cause problems. Coating your seals with a specialty material such as gold allows you to protect the fill fluid in your seal from becoming saturated by the hydrogen, ensuring that your measurement remains accurate through the duration of your project.

For more information, please download the product brochure

High Temperature Diaphragm Seals:

Bliss-Badotherm have developed a patented High Temperature Diaphragm Seal (HTDS) that can withstand temperatures of up to 1,112°F (600°C). This seal can be used for both gauge and differential pressure transmitters.

For more information, please download the product brochure

PTH Diaphragm Seal:

The PTH Diaphragm Seal construction is designed to make the differential or gauge pressure transmitter suitable for a direct manifold fit, meeting the requirements of the IEC 61518. The PTH is standard suitable for pressure measurement up to a maximum process temperature of 200°C. This can however be increased to higher temperatures when combined with different fill fluids. The wetted parts are all made from AISI 316(L), this can be varied depending on the process conditions.

For more information, please download the product brochure

LPG Diaphragm seal:

For processes that operate with very low pressures (< 100 mbar), Bliss Americas & Badotherm recommend a Low Gauge Pressure (LGP) Diaphragm Seal. With this solution it is possible to measure up to 5 mbar with minimal temperature effects.

For more information, please download the product brochure

Zirconium Seals:

Zirconium Seals are especially corrosion-resistant seals that are extremely effective for Urea Applications. While regular, stainless steel seals last approximately 4-6 months and tantalum approximately 10-12 months, Bliss-Badotherm's Zirconium Seals can be used for 3-4 years, making them a highly cost-effective and hassle-free solution.

For more information, please download the product brochure

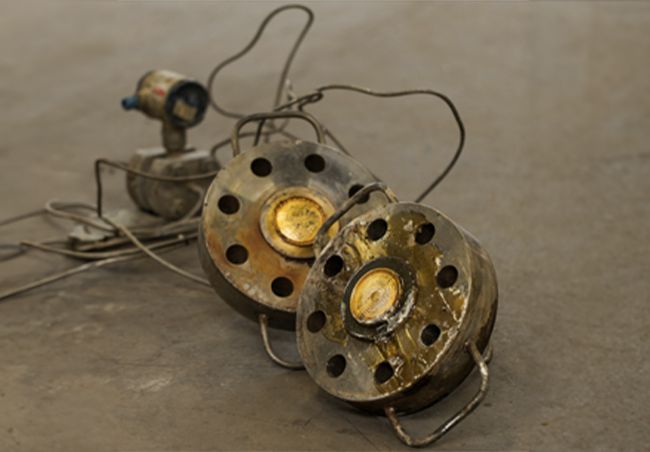

Diaphragm Seal Refurbishment Program:

Diaphragm seals are often subjected to harsh environments, rendering them damaged. High temperatures can ruin seals by heating fill fluids, and high pressure water jets, corrosive materials and dents can also cause damage. Bliss Anand understands that constantly replacing your diaphragm seals can get expensive, so we offer Diaphragm Seal Refurbishment Services. We will replace an old Diaphragm Seal from an existing transmitter-seal assembly at half the cost of a new transmitter-seal assembly, so you can get your project running smoothly again with minimal disturbance.

For more information, please download the product brochure

BaseCal:

Though you may be sure of your project specifications, requirements and variables, what you may not be sure about is which Diaphragm Seal will best suit your needs. That's where we come in. Bliss Anand and Badotherm bring you BaseCal, a web-based performance tool that helps you understand the effects of different variables and conditions on your diaphragm seal application.

For more information, please download the product brochure